Professional Dissolvers

Dissolvers are used in mixing processes requiring high shear rates, such as emulsification, solid dispersion and wet milling. High local shear forces are achieved through high peripheral speeds of the shearing elements located on the disc (support disc) of the mixing element, which most often take the shape of saw teeth. REDOR's offer is based primarily on medium and heavy dissolvers dedicated to industrial production processes.

Technical parameters of our devices

| Shaft seal: | Lip seal, water labyrinth seal |

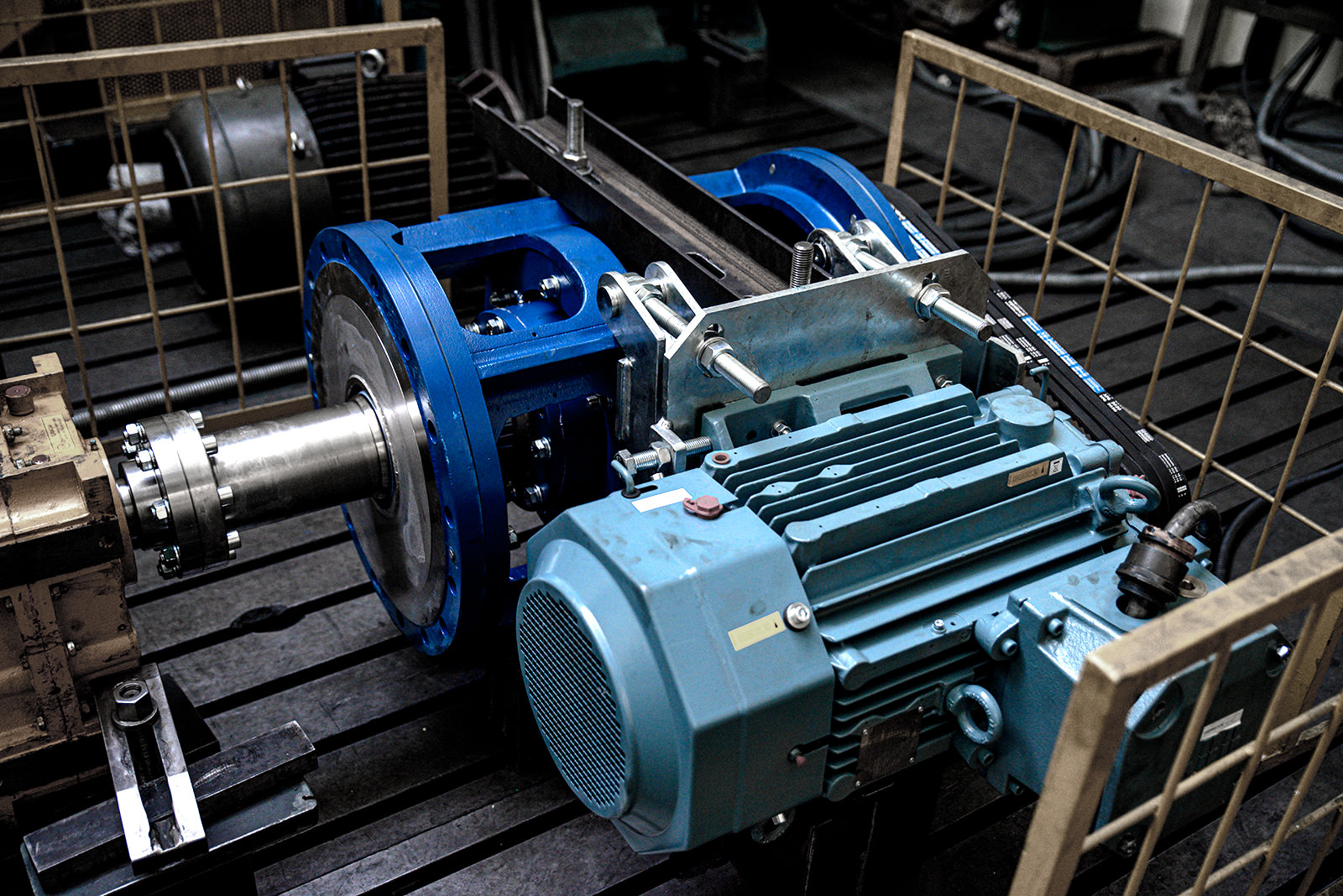

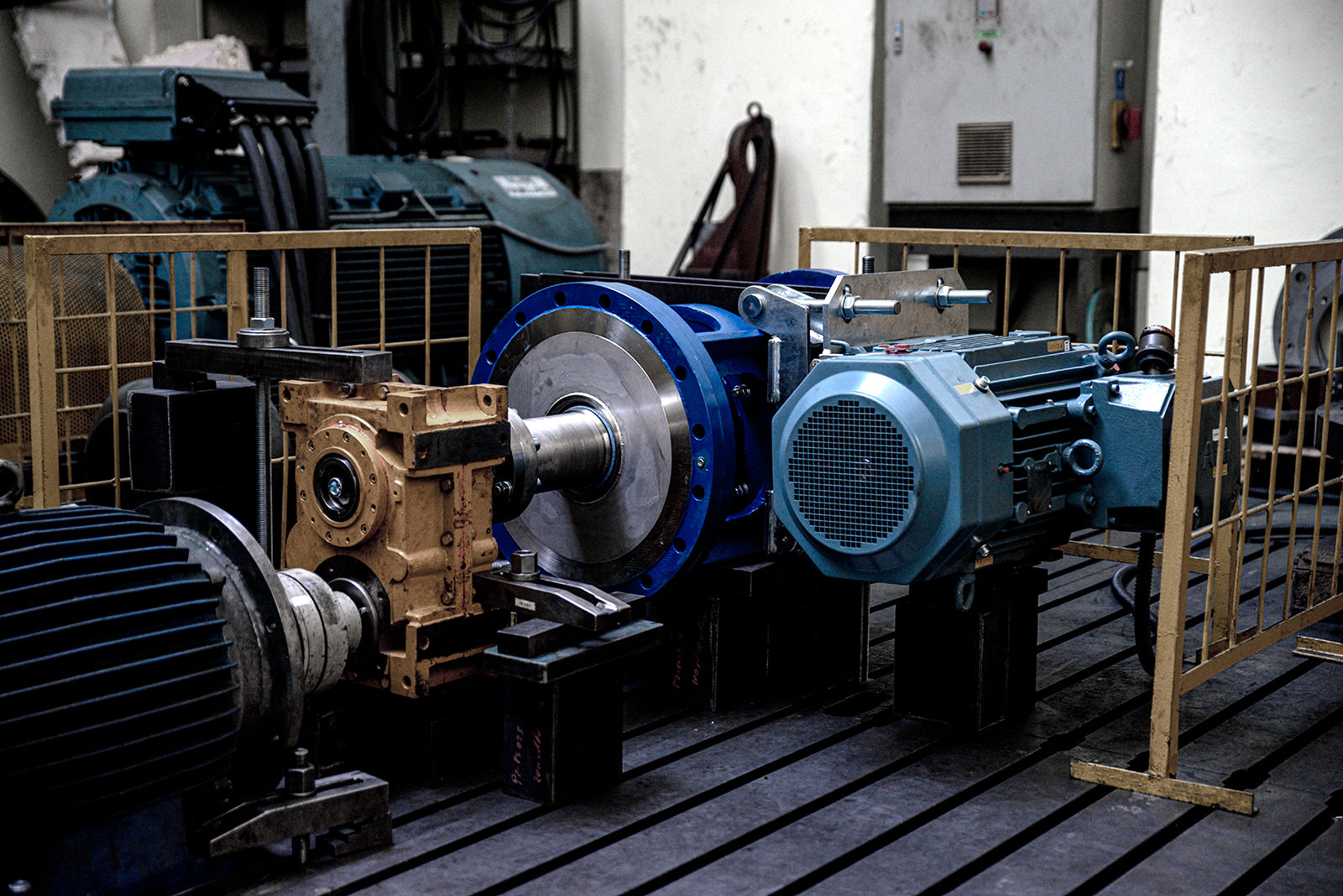

| Agitators drive: | Direct from the electric motor, belt transmission |

| Material inside the tank: | Carbon steel, stainless steel, Nickel alloys (e.g., C-276 / C-22), specialized coatings. |

Our selected services and devices

2023

- Delivery and assembly of dissolvers for aqueous solutions of cobalt sulphate

- Delivery of a 90kW dissolver for the paint rheology tank

- Delivery of a dissolver with a belt drive for the wood stain tank

2022

- Delivery and assembly of dissolver for aqueous solutions of cobalt sulphate

![]()

17.538,5mm in length inside the tank

The longest segmented shaft manufactured in our factory measures

![]()

ATEXQ Quality Certificate

In close cooperation with accredited certification bodies, we design and manufacture mixing units operating in explosion hazard zone "0".

CARE FOR DETAILS AND MATERIALS

determines the direction of production

Qualified machine operators, modern machinery fleet, machining engineers supported by CAM technology and 100% control measurements of tolerated actual dimensions ensure compliance of manufactured details with technical documentation. Combined with high requirements for suppliers of steel and commercial technical components, we ensure stable and high quality of the offered products